SKARGI-AFRICA ENGINEERING & CONSTRUCTION LTD

(We fix it right & safe)

SKARGI-AFRICA ENGINEERING & CONSTRUCTION LTD

(We fix it right & safe)

Bisha mining zinc copper cleaner & zinc copper plant phases 1, 2, &3

Client :

Bisha Mining Share Company

Location : Eritera

Schedule: (2015-2017)

Service Type:

Mining & Construction Services

Scope of Work – Bisha Mining Zinc Copper Cleaner & Zinc Copper Plant (Phases 1, 2 & 3)

Construction of Structural Framework for Zinc Copper Cleaner & Sulfide Plant

- Fabrication and erection of structural steel frameworks for the cleaner and sulfide plant.

- Installation of beams, columns, and supports for equipment and processing units.

- Application of corrosion-resistant coatings for durability in mining environments.

- Quality assurance checks to ensure structural stability and compliance with engineering standards.

Installation of Mechanical Pumps

- Positioning, alignment, and secure installation of pumps for ore processing and fluid transport.

- Integration of pumps with pipelines, valves, and control systems.

- Performance testing and commissioning to ensure operational efficiency.

- Routine maintenance and troubleshooting to prevent downtime.

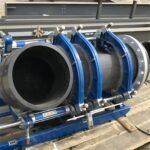

HDPE Pipe Fabrication and Welding

- Cutting, shaping, and welding of HDPE pipes to support fluid and slurry transport.

- Utilization of butt fusion and electrofusion welding techniques for high-strength joints.

- Pressure testing of installed HDPE pipelines to confirm leak-proof integrity.

- Compliance with environmental and industrial standards for pipeline installation.

On-Site Pipe Fitting Works

- Precision pipe fitting for process lines, water transport, and chemical distribution.

- Installation of flanges, couplings, and valves for seamless integration.

- Ensuring proper alignment and securing of pipes for optimal flow.

- Testing and inspection to verify system integrity and functionality.

Scaffolding Erection

- Assembly and installation of scaffolding to support high-elevation construction and maintenance.

- Compliance with safety regulations for working at heights.

- Load testing and certification of scaffolding structures before use.

- Dismantling and removal of scaffolding upon project completion.

Rigging and Lifting of Structural Steels & Heavy Components

- Safe rigging and lifting of steel frameworks, processing equipment, and structural components.

- Use of certified lifting gear, slings, and cranes to ensure precision and safety.

- Coordination with engineers and site supervisors for efficient material handling.

- Adherence to weight limits and load distribution requirements.

Unloading and Handling of Site Materials (De-Stuffing)

- Offloading and organizing construction materials, heavy equipment, and containers.

- Inspection of received materials to verify compliance with project specifications.

- Proper storage and handling to prevent material loss or damage.

- Coordination with logistics teams to optimize workflow.

Lifting and Positioning of Heavy Structures and Containers

- Planning and execution of heavy lifting operations for plant construction and equipment installation.

- Use of cranes, hoists, and rigging systems for precise placement of components.

- Adherence to safety protocols to prevent accidents and structural damage.

- Verification of load capacities and secure attachment before lifting.

EXI Electricals, Instrumentation, and Commissioning

- Installation of electrical systems, including power distribution, control panels, and wiring.

- Implementation of process instrumentation for monitoring plant operations.

- Testing, calibration, and commissioning of electrical and instrumentation systems.

- Compliance with safety and regulatory standards for electrical installations.

- PROGRESS PICTURES & VIDEOS OF PROJECT

Call us:(+233)0593843221

Call us:(+233)0593843221  Email Us Now

Email Us Now