SKARGI-AFRICA ENGINEERING & CONSTRUCTION LTD

(We fix it right & safe)

SKARGI-AFRICA ENGINEERING & CONSTRUCTION LTD

(We fix it right & safe)

Newmont Ahafo Mill Expansion

Scope of Work

Client :

Stetanutti Stocks & DRA, WEC, Skargi-Africa

Location : Ghana

Schedule: (2021-2022)

Service Type:

Mining & Construction Services

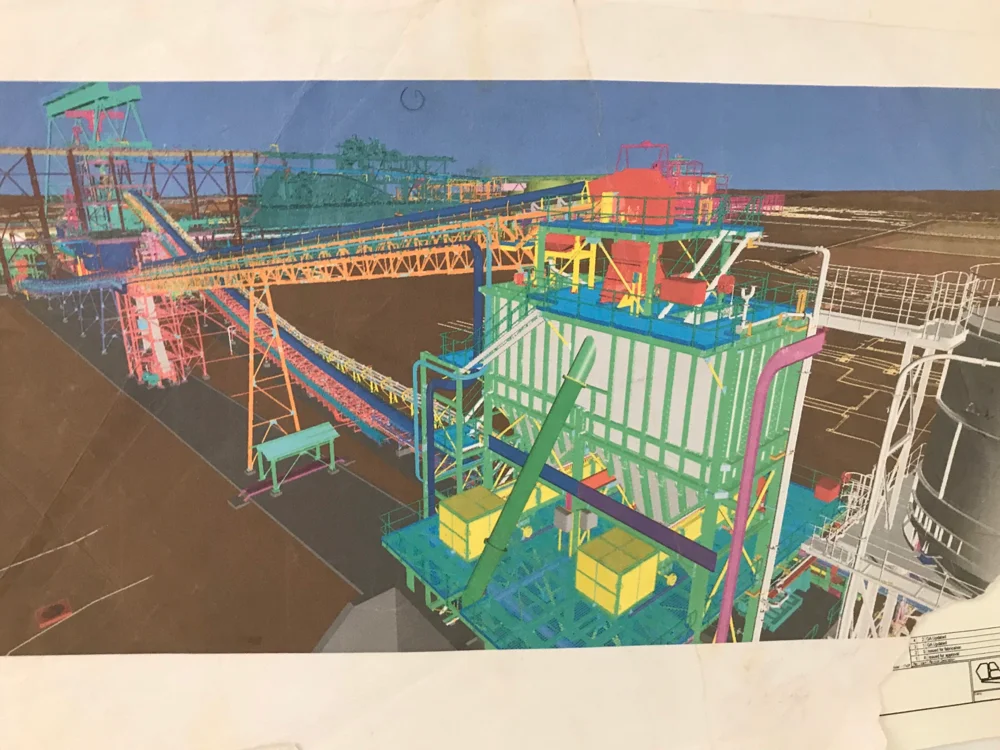

Scope of Work – Newmont Ahafo Mill Expansion Project (Ghana)

Structural Steel Erection of Primary Crusher Building

- Fabrication, assembly, and installation of structural steel frameworks for the Primary Crusher (Pubber Crusher) Building.

- Alignment, bolting, and welding of steel beams, columns, and support structures.

- Load testing and quality control to ensure compliance with engineering standards.

- Application of protective coatings to prevent corrosion and enhance durability in mining environments.

On-Site Fabrication, Steel Work, and Modifications

- Cutting, welding, and shaping of steel components to fit project specifications.

- Modifications to existing structures to accommodate new installations or upgrades.

- Reinforcement of steel sections for enhanced load-bearing capacity.

- Compliance with safety standards for welding and fabrication work on-site.

Installation of 1200 Tons of Structural Steel

- Lifting, positioning, and assembling a notable quantity of 1200 tons of structural steel components.

- Coordination of logistics for efficient material handling and timely installation.

- Use of certified rigging and lifting techniques to ensure safety and precision.

- Inspection and structural integrity testing before commissioning.

Installation of Structural Steel Conveyor (Conveyor 1 & 2) to the Mill Area

- Erection and alignment of Conveyor 1 & 2 to facilitate material transport to the mill.

- Installation of conveyor trusses, support frames, walkways, and guardrails.

- Integration of conveyor belts, rollers, and tensioning systems.

- Testing and commissioning to ensure smooth and efficient operation.

The Newmont Ahafo Mill Expansion Project ensures:

- Enhanced Processing Capacity – Structural expansion to support increased ore processing efficiency.

- Durable and Safe Infrastructure – Installation of 1200 tons of structural steel to reinforce mining operations.

- Efficient Material Handling – Conveyor system installation for seamless ore transportation to the mill.

- Precision Engineering & Modifications – On-site fabrication and structural adjustments for optimal performance.

- Operational Safety & Compliance – Adherence to industry standards for welding, lifting, and structural integrity.

- Minimized Downtime – Efficient execution to reduce disruptions in mining and milling operations.

- PROGRESS PICTURES & VIDEOS OF PROJECT

Call us:(+233)0593843221

Call us:(+233)0593843221  Email Us Now

Email Us Now